Did you catch the news about the construction of TSMC's new plant in Chiayi uncovering some archaeological remains? This plant, currently under construction, is actually set to produce CoWoS technology, one of the hottest sectors fueled by the recent AI wave. So, what exactly does CoWoS mean?

For people who are interested in semiconductor industry, you can also read more introduction in Taiwan Industry 101: Semiconductor

What is CoWoS

CoWoS is a 2.5D packaging technology, which stands for "Chip on Wafer on Substrate." By stacking chips, wafers, and substrates, it reduces the distance between chips, enhancing performance, reducing heat, and shrinking overall size. "CoW" refers to the "Chip-on-Wafer" stacking, and "WoS" means "Wafer-on-Substrate," which is the wafer stacked on the substrate. In order to understand why we need CoWos packaging technology, we would first need to discuss advanced semiconductor processes. The commonly heard 3nm and 5nm processes in semiconductor manufacturing refer to gate lengths, a key measure of process advancement. Smaller gate lengths indicate more advanced technology and higher transistor density per chip.

In addition to improving technology to shrink gate lengths, we can also enhance efficiency by stacking different chips using advanced packaging techniques, achieving heterogeneous integration. Stacking chips reduces space requirements, lowers power consumption, and boosts performance.

CoWoS Basic Technology

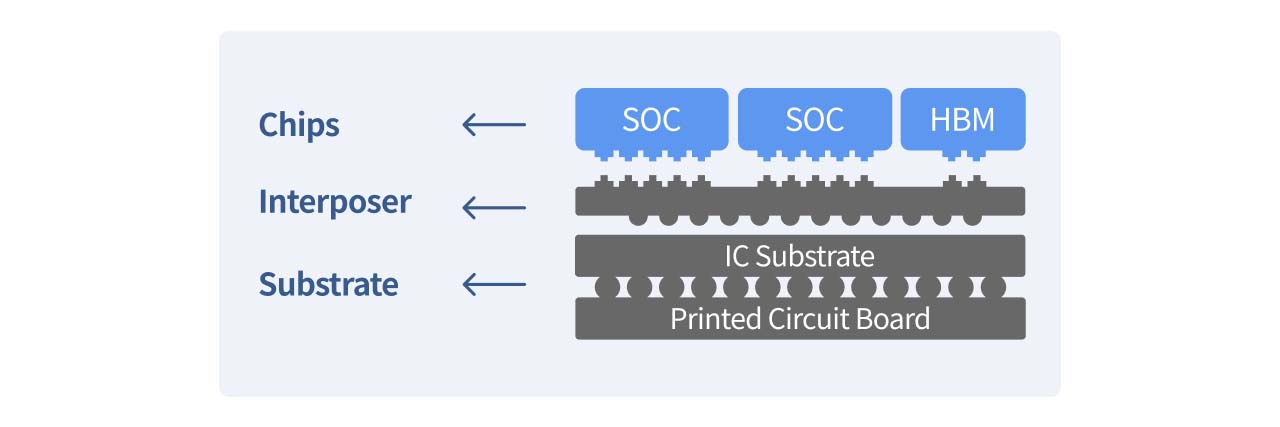

Now, let's break down the CoWoS packaging concept from the bottom up, covering key technologies and components involved.

1. PCB and IC Substrate

Both PCB (Printed Circuit Board) and IC substrate serve similar functions, including providing power connections, signal transmission, structural support, and heat dissipation. IC substrates are typically used for high-density, high-performance chip integration, while PCBs connect the package substrate to external circuits. These two components work together in CoWoS packaging to deliver high-performance, high-density, and highly reliable solutions.

2. Interposer

The interposer acts as the electrical connection between multiple IC chips and between IC chips and the substrate, ensuring signal transmission and power distribution. It allows chips made with different process technologies to integrate within the same package, supporting multifunctional systems and computing applications.

3. Chips and Memory

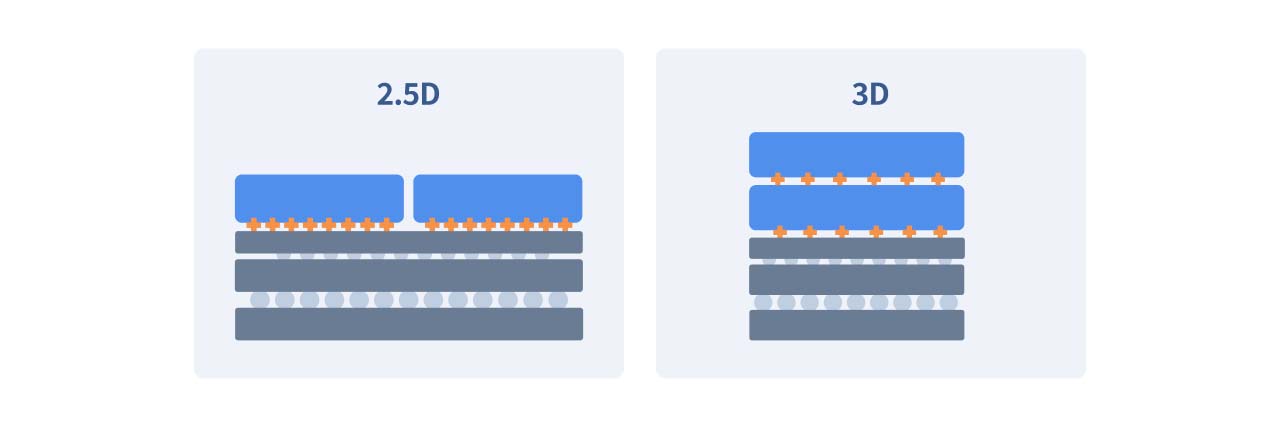

At this stage, SoC and HBM chips are placed for packaging. Vertical stacking is done between the PCB and interposer (3D), while SoC and HBM chips are currently arranged horizontally (2D). This combination of vertical and horizontal arrangements is what makes it 2.5D packaging. Looking forward, the industry hopes to also commercialize 3D stacking for SoC and HBM chips, pushing for broader adoption of 3D technology.

The Emergence and Applications of CoWoS

About 10 years ago, TSMC first introduced CoWoS technology to improve the integration and performance of semiconductor devices. Despite TSMC’s push for commercialization, CoWoS was not widely adopted at the time due to high costs, while the lower-cost InfO (Integrated Fan-Out) technology became more popular.

| InfO | CoWoS |

|---|---|

| Lower cost, thinner, better heat dissipation | Higher cost, focused on high performance, ideal for advanced computing and data centers |

However, the recent explosion in AI development has led to a surge in GPU demand. AI computing requires processing massive data at high performance levels, which has driven up the demand for more advanced packaging technologies. CoWoS, with its ability to stack multiple chips on the same wafer and connect them to the substrate, provides a high-density, high-performance solution. As a result, CoWoS is now in the spotlight.

CoWoS-Related Supply Chain

As the exclusive owner of CoWoS technology, TSMC (2330) is the biggest winner in this surge, with demand outstripping supply for its advanced packaging capacity. While TSMC holds the patents and technology, it still relies on upstream equipment suppliers. Key equipment such as wet processing, die sorting, and automated optical inspection (AOI) tools are essential, benefiting companies such as Scientech Corporation (3583), All Ring Tech (6187), C Sun Manufacturing (2467), and Grand Process Technology (3131). These companies are all having positive growth recently.

For the materials involved in CoWoS manufacturing, including PCBs, IC substrates, and interposers, suppliers like WUS Printed Circuit (2316), Unimicron (3037),UMC (2303) have also gained from the AI-driven demand.

Lastly, in terms of testing and assembly, as CoWoS orders surge, while the highest-end processes remain with TSMC, more basic packaging tasks like Wafer-on-Substrate (WoS) have been outsourced to ASE Technology (3711), King Yuan Electronics (2449).

All of these companies stand to benefit from the CoWoS boom, and their recent performance is worth watching closely.

For people who are interested in AI industry, check out the following articles.

Taiwan Industry 101: Semiconductor